北方农业学报 ›› 2023, Vol. 51 ›› Issue (5): 84-92.doi: 10.12190/j.issn.2096-1197.2023.05.09

槲寄生多糖提取工艺优化及抗氧化活性研究

蒋大珍, 马佰诚, 杨皎, 罗进城, 孙雪薇, 李佳琳

- 佳木斯大学 公共卫生学院,黑龙江 佳木斯 154007

Study on the optimization of mistletoe polysaccharide extraction process and the antioxidant activities

JIANG Dazhen, MA Baicheng, YANG Jiao, LUO Jincheng, SUN Xuewei, LI Jialin

- College of Public Health,Jiamusi University,Jiamusi 154007,China

摘要:

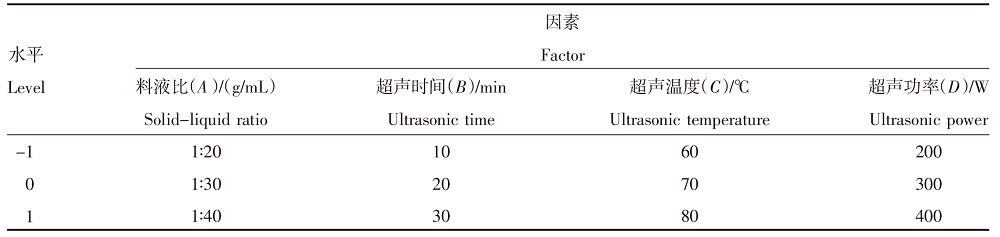

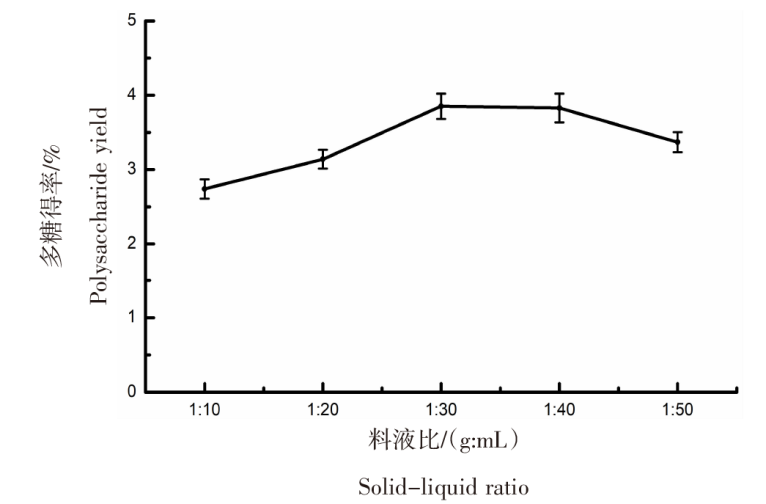

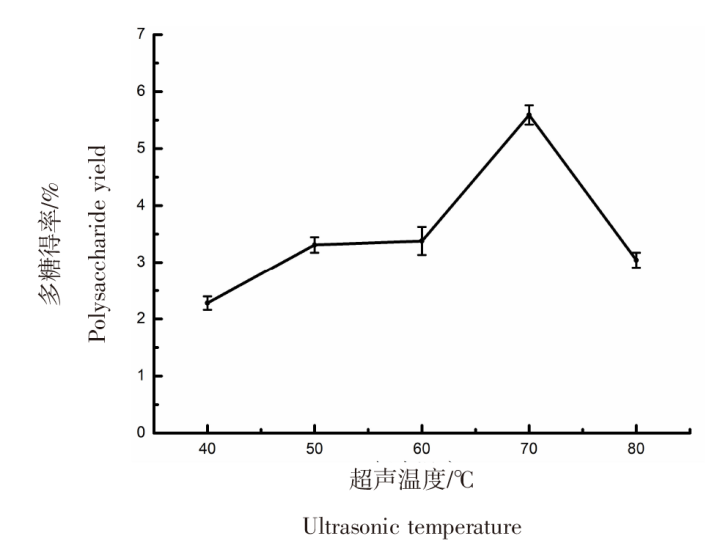

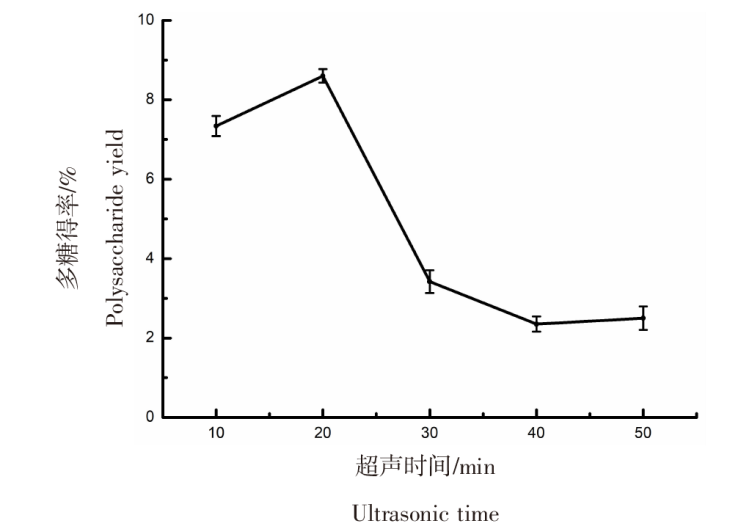

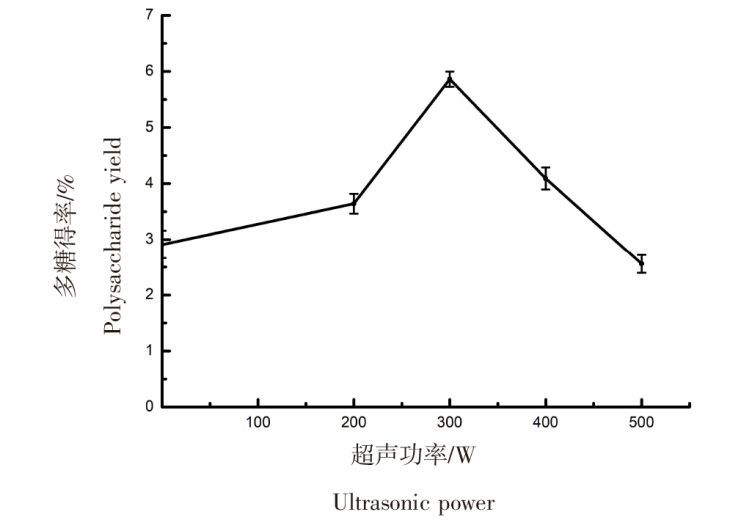

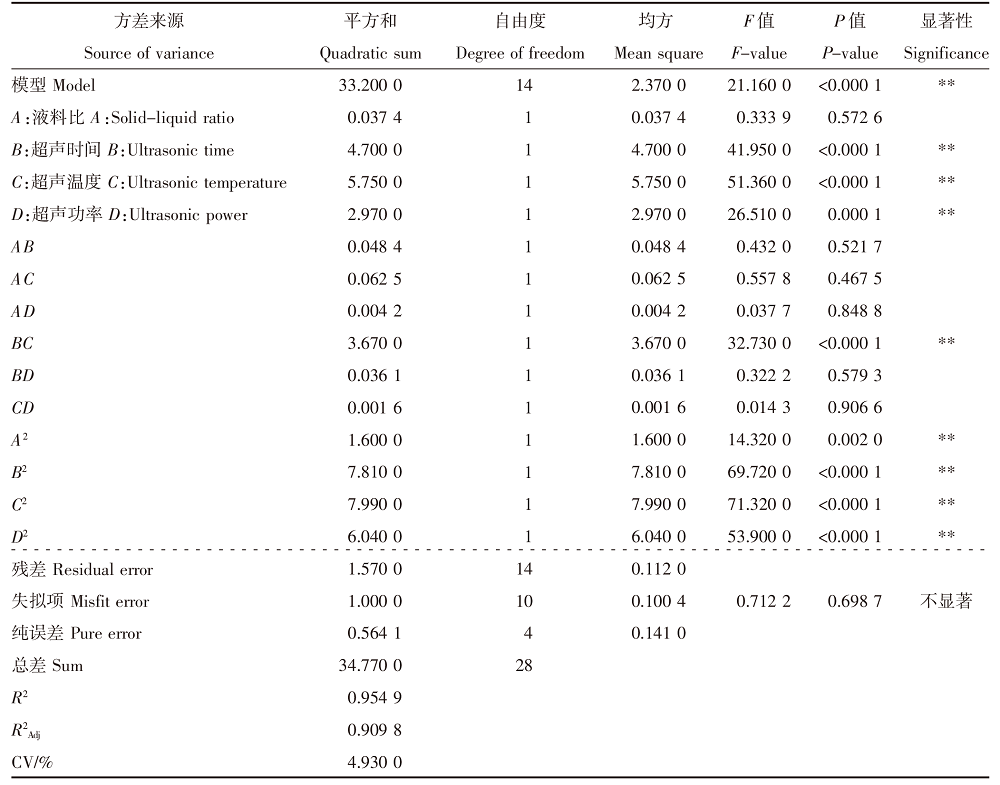

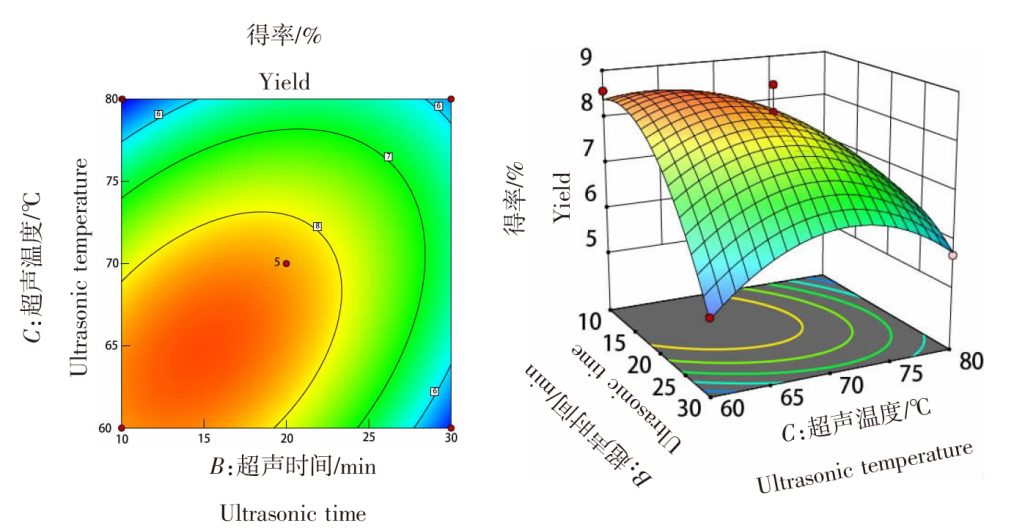

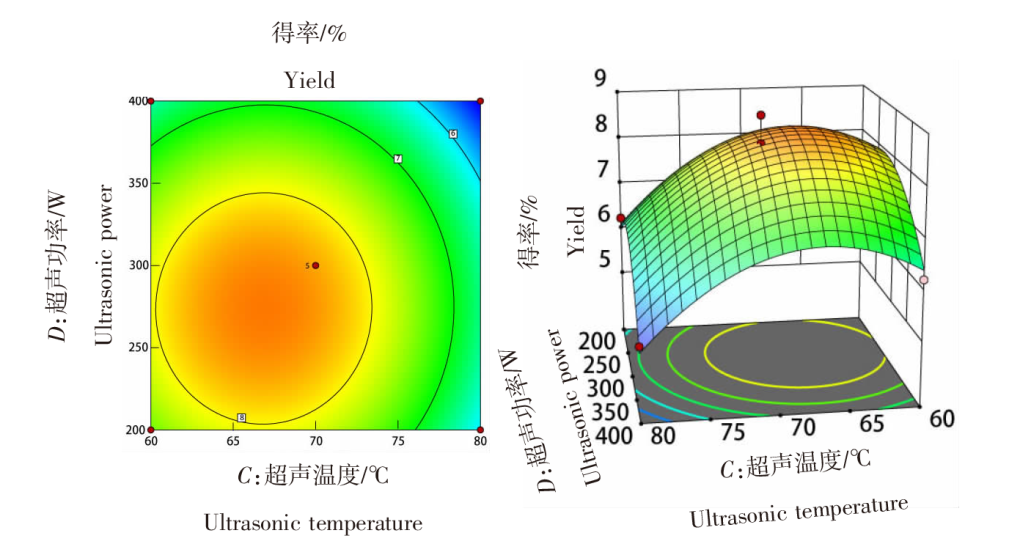

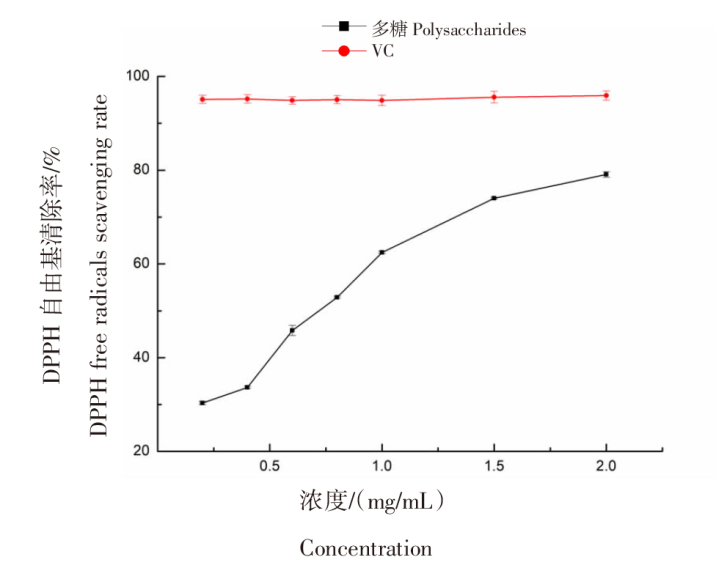

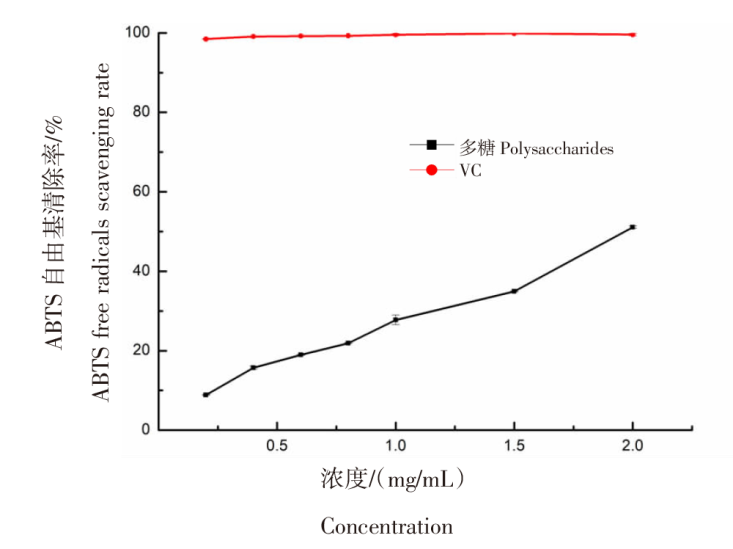

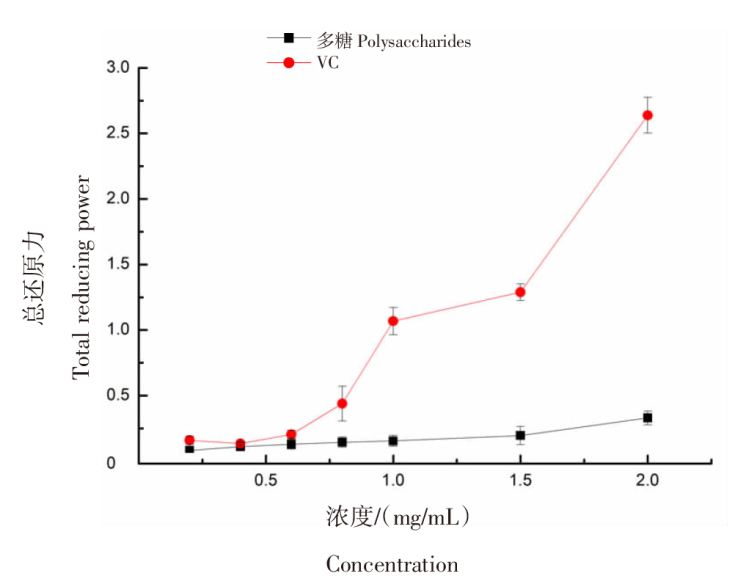

【目的】优化槲寄生多糖提取工艺,探究抗氧化活性,为槲寄生多糖提取及有效利用提供参考。【方法】以多糖得率为考查指标,采用单因素试验方法分析料液比、超声时间、超声温度、超声功率对槲寄生多糖得率的影响;运用响应面法对槲寄生多糖提取工艺进行优化,并测定槲寄生多糖对DPPH自由基、ABTS自由基的清除能力及对三价铁离子的总还原力。【结果】不同因素水平下,料液比1∶30(g∶mL)、超声温度70 ℃、超声时间20 min、超声功率300 W时,对应的槲寄生多糖得率最高,分别为3.85%、5.59%、8.60%、5.86%,对槲寄生多糖得率的影响为超声温度>超声时间>超声功率>料液比;响应面法优化结果:料液比1∶29(g∶mL)、超声时间15 min、超声温度64 ℃、超声功率300 W时,槲寄生多糖得率最高,为8.17%。2 mg/mL多糖溶液对DPPH自由基、ABTS自由基的清除能力分别为79.07%、51.38%,IC50分别为0.612、2.611 mg/mL;对三价铁离子的总还原力为0.33。【结论】槲寄生多糖的最佳提取工艺为:料液比1∶29(g∶mL)、超声时间15 min、超声温度64 ℃、超声功率300 W;槲寄生多糖对DPPH自由基、ABTS自由基均有清除作用,对三价铁离子具有还原作用。

中图分类号:

- TS209