| [1] |

PECKA E, DOBRZANSKI Z, ZACHWIEJA A, et al. Studies of composition and major protein level in milk and colostrum of mares[J]. Animal Science Journal, 2012, 83(2): 162-168.

doi: 10.1111/j.1740-0929.2011.00930.x

pmid: 22339698

|

| [2] |

GUY M, MARIE-FRANÇOISE M, CHRISTINE L, et al. Proteomic tools to characterize the protein fraction of Equidae milk[J]. Proteomics, 2004, 4(8): 2496-2509.

pmid: 15274143

|

| [3] |

PIESZKA M, ŁUSZCZYNSKI J, ZAMACHOWSKA M, et al. Is mare milk an appropriate food for people? -A review[J]. Annals of Animal Science, 2016, 16(1): 33-51.

doi: 10.1515/aoas-2015-0041

|

| [4] |

DANKOW R, WOJTOWSKI J, PIKUL J, et al. Effect of lactation on the hygiene quality and some milk physicochemical traits of the Wielkopolska mares[J]. Archiv Fur Tierzucht, 2006, 49(special issue):201-206.

|

| [5] |

张猛, 党娜, 孟和毕力格, 等. 基于Pac-Bio单分子实时测序技术比较酸马奶和生马奶中细菌多样性[C]// 第十五届益生菌与健康国际研讨会摘要集. 南京: 中国食品科学技术学会, 2020:91-92.

|

| [6] |

查哈达. 酸马奶治疗肺结核56例临床观察[J]. 中国民族民间医药, 1999, 8(1): 13-14.

|

| [7] |

原琪, 赵淑萍, 乌云高娃, 等. 酸马奶治疗冠心病62例临床观察[J]. 医药世界, 2006(12): 111-112.

|

| [8] |

敖其, 王丹, 包英姝, 等. 酸马奶对慢性胃炎患者临床症状的改善效果研究[J]. 中国乳品工业, 2018, 46(5): 14-17.

|

| [9] |

布图雅. 溃疡性结肠炎的蒙医治疗特色与优势[J]. 世界科学技术(中医药现代化), 2009, 11(1): 75-79.

|

| [10] |

孟和毕力格, 乌日娜, 王立平, 等. 不同地区酸马奶中乳杆菌的分离及其生物学特性的研究[J]. 中国乳品工业, 2004, 32(11): 6-11.

|

| [11] |

孙天松, 王俊国, 张列兵, 等. 中国新疆地区酸马奶中乳酸菌生物多样性研究[J]. 微生物学通报, 2007, 34(3): 451-454.

|

| [12] |

刘文俊, 多拉娜, 刘亚华, 等. 基于纯培养方法和PacBio三代测序技术研究蒙古国传统酸马奶中乳酸菌多样性[J]. 中国食品学报, 2019, 19(4): 27-37.

|

| [13] |

赵美霞. 内蒙古地区酸马奶酒中酵母菌的分离鉴定及抗菌特性的研究[D]. 呼和浩特: 内蒙古农业大学, 2002.

|

| [14] |

李盘盘, 马凤莲, 孙梦莹, 等. 具有蛋白水解特性的酵母菌改善商业发酵剂发酵乳特性[J]. 现代食品科技, 2023, 39(4): 71-80.

|

| [15] |

SAVIJOKI K, INGMER H, VARMANEN P. Proteolytic systems of lactic acid bacteria[J]. Applied Microbiology and Biotechnology, 2006, 71(4): 394-406.

doi: 10.1007/s00253-006-0427-1

pmid: 16628446

|

| [16] |

刘敬兰. 马克思克鲁维酵母对发酵乳中蛋白质代谢的影响[D]. 长春: 吉林农业大学, 2015.

|

| [17] |

夏亚男, 刘皓, 双全. 基于宏基因组分析酸马奶的微生物多样性及功能基因[J]. 中国食品学报, 2022, 22(2): 301-309.

|

| [18] |

马嵬, 金素钰, 郑玉才. 酸奶中游离氨基酸含量及乳清蛋白组成分析[J]. 中国乳品工业, 2006, 34(6): 20-22.

|

| [19] |

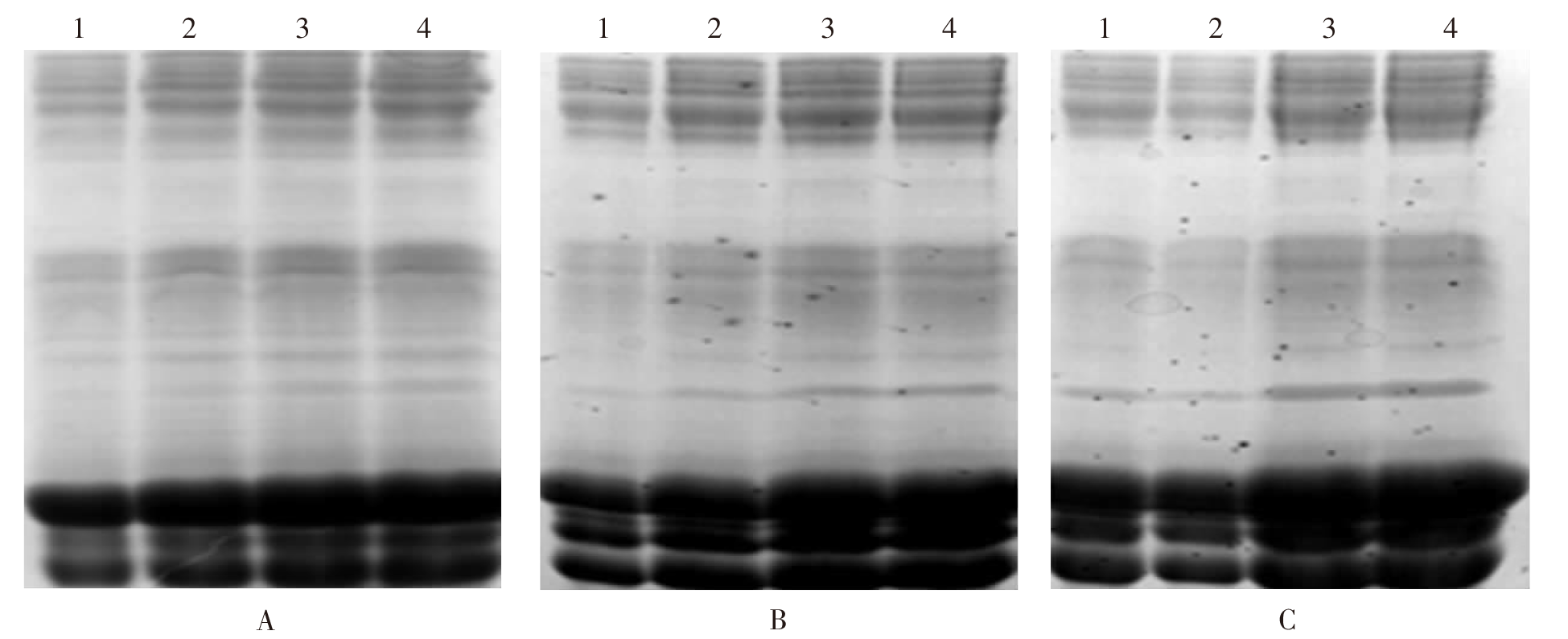

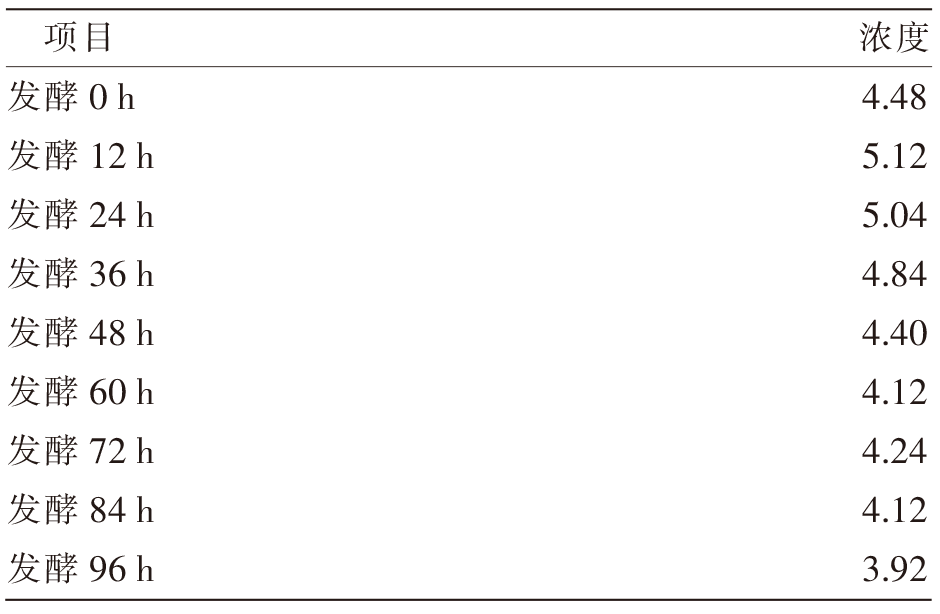

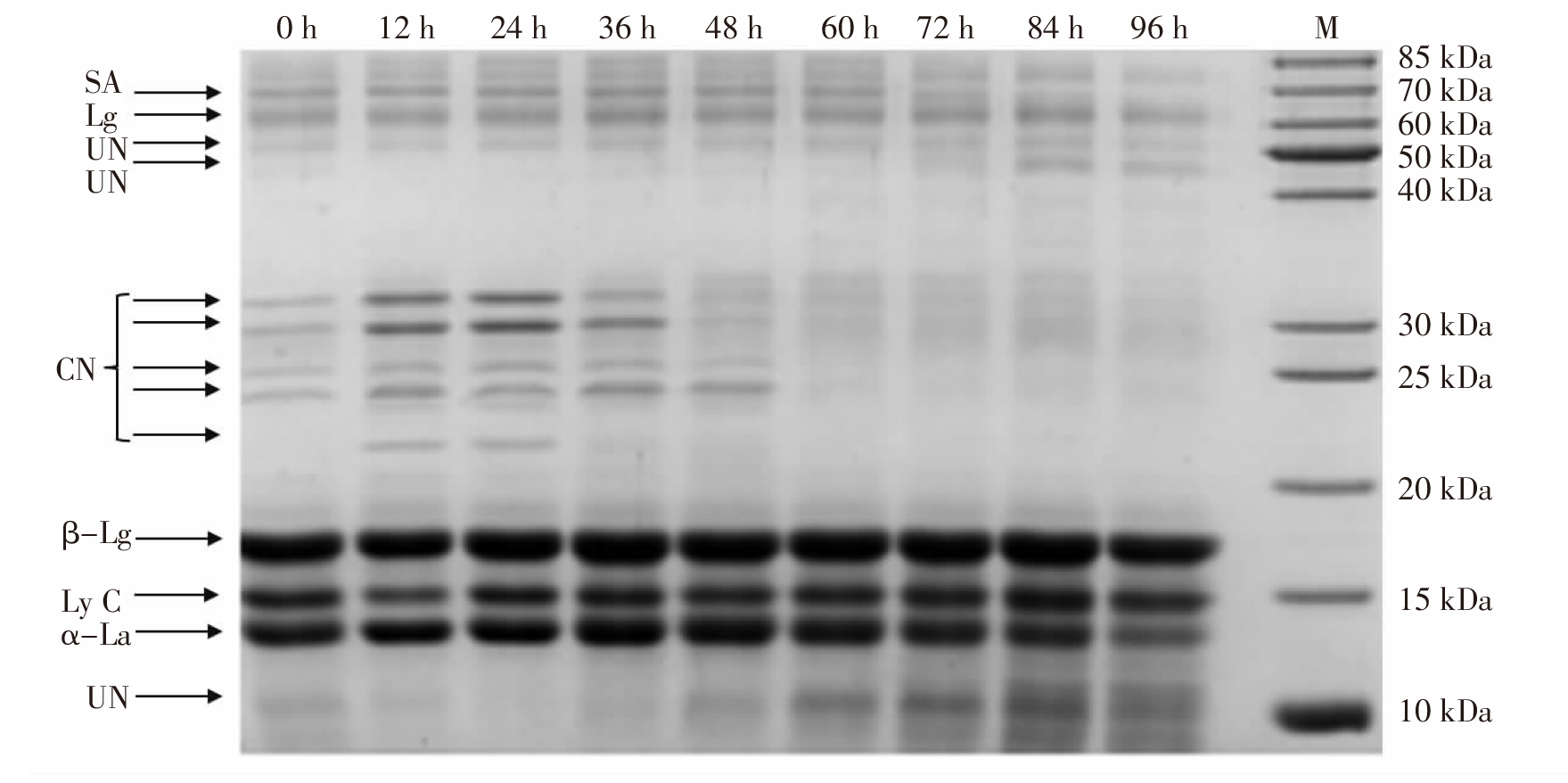

孟岳成, 黃阮卿, 陈杰, 等. 热处理对酸马奶中蛋白质稳定性的影响[J]. 中国食品学报, 2022, 22(12): 174-180.

|

| [20] |

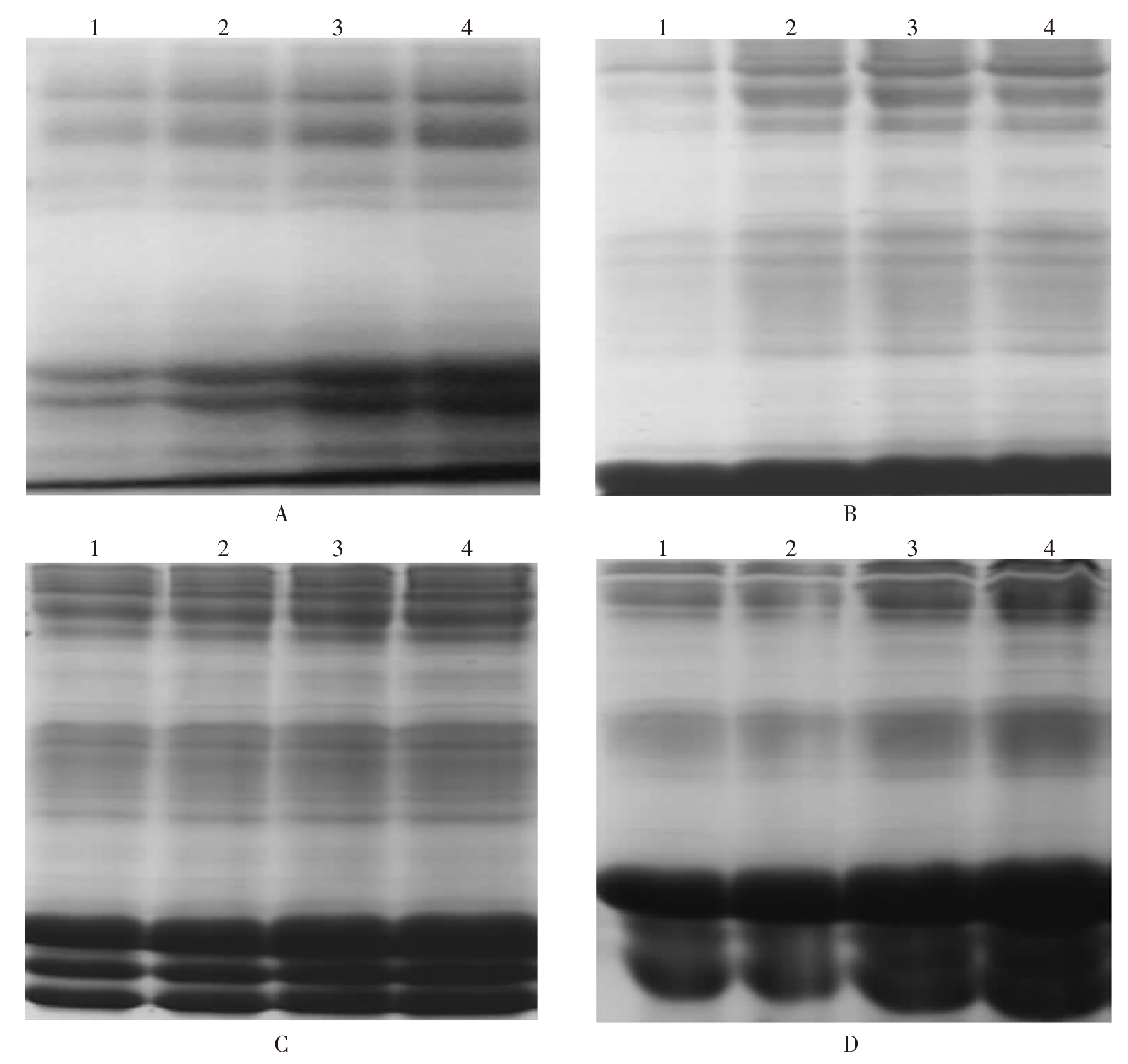

侯艳霞, 古丽巴哈尔·卡吾力, 高晓黎. SDS-PAGE电泳法对4种鲜奶蛋白质组分的分析研究[J]. 新疆医科大学学报, 2017, 40(5): 646-650,658.

|

| [21] |

古丽巴哈尔·卡吾力, 李玲, 常占瑛, 等. 鲜马奶乳清蛋白质组学研究[J]. 中国乳品工业, 2018, 46(9): 13-18.

|

| [22] |

MARTUZZI F, DOREAU M. Mare milk composition: Recent findings about protein fractions and mineral content[M]//MIRAGLIA N,MARTIN-ROSSET W. Nutrition and feeding of the broodmare. Wageningen: Wageningen Academic Publishers, 2006.

|

| [23] |

SCHRYVER H F, OFTEDAL O T, WILLIAMS J, et al. A comparison of the mineral composition of milk of domestic and captive wild equids (Equus przewalski, E. zebra, E. burchelli, E. caballus, E. assinus)[J]. Comparative Biochemistry and Physiology Part A:Physiology, 1986, 85(2): 233-235.

doi: 10.1016/0300-9629(86)90244-6

|

| [24] |

张心怡, 姜杨, 刘小鸣, 等. 基于肽组学的瑞士乳杆菌酪蛋白水解差异分析[J]. 中国食品学报, 2022, 22(6): 53-61.

|

| [25] |

RYHÄNEN E L, PIHLANTO-LEPPÄLÄ A, PAHKALA E. A new type of ripened, low-fat cheese with bioactive properties[J]. International Dairy Journal, 2001, 11(4/5/6/7): 441-447.

doi: 10.1016/S0958-6946(01)00079-6

|

| [26] |

GOBBETTI M, MINERVINI F, RIZZELLO C G. AngiotensinI-converting-enzyme-inhibitory and antimicrobial bioactive peptides[J]. International Journal of Dairy Technology, 2004, 57(2/3): 173-188.

doi: 10.1111/idt.2004.57.issue-2-3

|

| [27] |

XIA Y N, YU J Q, XU W H, et al. Purification and characterization of angiotensin-Ⅰ-converting enzyme inhibitory peptides isolated from whey proteins of milk fermented with Lactobacillus plantarum QS670[J]. Journal of Dairy Science, 2020, 103(6): 4919-4928.

doi: 10.3168/jds.2019-17594

|

| [28] |

布仁其其格, 高雅罕, 任秀娟, 等. 不同发酵时期酸马奶细菌群落结构[J]. 食品科学, 2016, 37(11): 108-113.

doi: 10.7506/spkx1002-6630-201611019

|